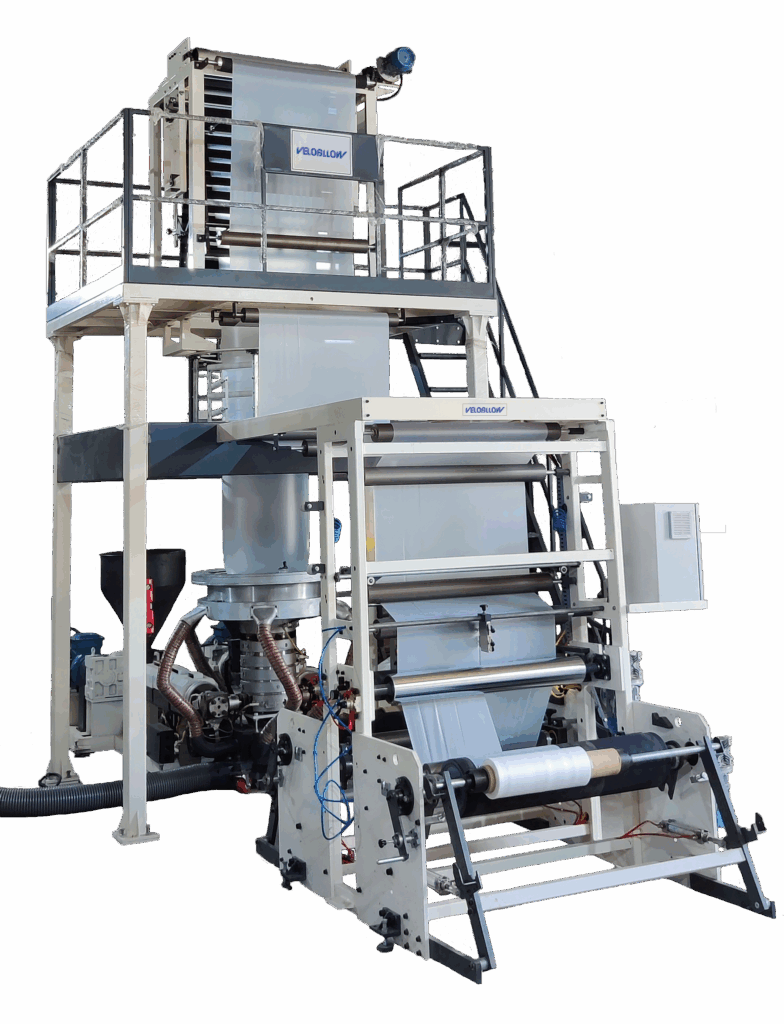

ABA 2 LAYER BLOWN FILM PLANT EXTRUDER

Three Layers. Two Extruders. One Smart Solution.

The ABA / 2 LAYER BLOWN FILM EXTRUSION PLANT is designed to maximize productivity and minimize energy consumption. The advanced screw and gearbox system enables high output with exceptional film quality — ideal for today’s competitive packaging industry.

It Features two Extruders and a three-layer die which allows the machine to produce both 2-layer and 3-layer films, delivering greater flexibility, strength and cost-efficiency. One extruder feeds the outer layer and the second extruder feeds the middle layer.

Key Features:

ABA 2 LAYER BLOWN FILM DH/LD MODELS

Vishva GlobalX VELOBLLOW ABA SERIES offers advanced 2-layer and 3-layer blown film extrusion capabilities for HDPE and LDPE applications. These machines are engineered for efficiency, durability and superior film quality, making them ideal for a wide range of packaging solutions.